As a demonstrating blacksmith, travelling throughout the south-east and talking to people about my craft, I have found, to my surprise and dismay that a large percentage of the population have no idea what a blacksmith is or what a blacksmith does. This is most unfortunate because prior to the industrial revolution, the blacksmith was as common as grass in a hayfield.

So what is a blacksmith?

What is their historical signifigance?

Is there a place for the blacksmith in modern society?

#1

What is a blacksmith?

Webster's 1828 dictionary defines the blacksmith as follows:

"Blacksmith: A smith who works in iron, and makes iron utensils; more properly, an iron-smith."

Seeing that a "blacksmith" is "a smith who works in iron," we should also discover the meaning of the word "smith."

"Smith: Literally, the striker, the beater; hence, one who forges with the hammer; one who works in metals; as an iron-smith..."

So a blacksmith is a smith that works with iron, or in modern terms, steel.

The general method used to work the metal is to heat it in some sort of furnace or forge, and then use two elements to move and shape the metal. These two elements are force and resistance!

The force comes in the form of a hammer! I don't know if the first blacksmith tried using his hand as the source of force, but if so, he probably changed his mind pretty quick.

There are a wide variety of hammers for specific jobs like ball peen, cross peen, sledge, rounding, texturing, tooling, etc.

A cross peen or a sledge hammer is usually the preferred choice for a general work hammer. The general work hammers usually range from 2-4 pounds in weight, depending on the size and strength of the smith.

Left to right:

two-and-a-half-pound cross peen (texturing hammer,) three-pound sledge (for general forge work,) four-pound sledge (for heavy forge work or when I'm feeling stronger than I really am,) two-pound ball peen tooling hammer (hardened tools mar the hammer face so I have a hammer dedicated to tooling,) one pound ball peen (for small work,) eight-ounce ball peen (on bottom: for really small work)

The second element that is brought into play is resistance. If the blacksmith held the metal in the open air with nothing under it, he could hammer on it all day long and get nothing done! There must be something with mass, beneath the steel to provide a smashing resistance to each hammer blow. Whatever is placed beneath the steel to withstand this hammering, must be of sufficient strength and size to tolerate years of brutal and heavy use.

Over the years, blacksmiths improved the mass on which they hammered until the blacksmith anvil was born. The anvil can be simply a hefty hunk of metal, a rail-road rail, a flat piece of granite, or your older sister's head! (The last mentioned is certainly hard enough!)

However, an efficent shape of anvil for the blacksmith's work is found in the London Pattern anvil, which is the type of anvil generally portrayed in our imagination. It is characterized by two key features: the horn and the face. The larger the anvil, the more resistance it provides, and the more efficient the blacksmith's individual hammer blows become.

This is an English-made Trenton "London" pattern anvil that weighs 86 lbs!

This is another London pattern anvil that was made in America in the mid 1900's. It is a Fisher anvil, weighing 280 pounds!

This shows the two key features of the anvil.

The face is for general forge work and the horn is for curling or scrolling metal.

Employing these three elements - heat from the forge, force from the hammer, and resistance from the anvil - the blacksmith is able to move steel as he pleases according to his skill!

Pushing, pulling, flattening, smashing, rolling, welding, bending, rounding, enlarging, thinning.......IT IS ALL POSSIBLE!

Here is how the process works:

First the forge fire is lit. Coal is the fuel, and once it has caught fire, an air blast will get the fire somewhere around 2500 degrees Fahrenheit.

At the beginning of a long day's work, the craftsman carefully sifts the coal to remove impurities that melted out during the last fire, and also to remove excess ash which prevents the fire from getting as hot.

Cardboard or paper is used to get the fire started. The fire is contained in a small deep spot in the forge, known as the firepot!

If started properly, the fire is up to temperature in about five minutes. A piece of metal is then slid horizontally across the firepot to begin heating it.

When steel has reached its proper forging temperature, it is white in color. New smiths (and sometimes experienced smiths) are prone to remove the metal from the fire and attempt to work it at a red or dull orange color. This takes too much energy and wears the smith out. A good habit is to be patient and allow the steel to reach a good white color. This is approximately 2000-2200 degrees. For finishing or smoothing metal, a cooler temperature is ideal. Steel begins to burn at around 2350 degrees, so it is not desirable to reach that temperature.

The most efficient brush for quick scale removal is a butcher block brush. It has wide flat teeth. The brush is pictured along with some scale in this next photo!

Once the metal is brushed, it is time to shape the metal as needed.

The end result is controlled by the smith as desired through an endless variety of hammer technique.

Taper!

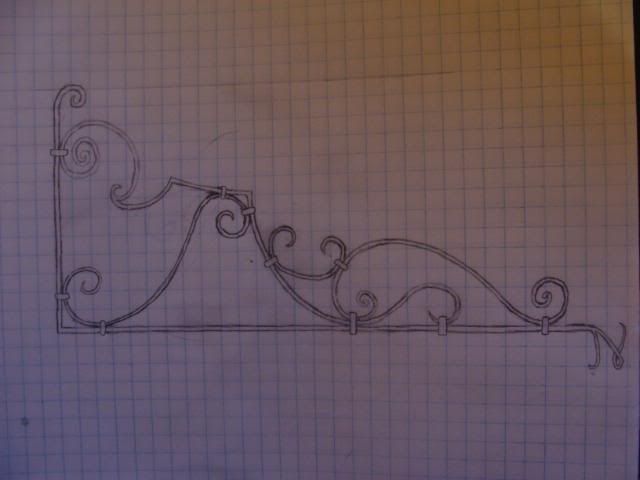

Fish-tail scroll!

Plain taper scroll!

Penny-foot scroll!

Twist!

Scroll and collar joint!

In addition to the basic tools, there is a wide range of hand-held tools like chisels, punches, tongs, vises, and other tools used for forming, cutting, and shaping the steel. The tools can be so varied in shape and intended use that any one blacksmith would be hard-pressed to identify another smith's tools and their purpose. Many times, a tool must be fabricated for a specific job that the smith is faced with, and once that job is complete, the smith may never need the tool again.

Each tool stands at attention in its location. From use, the shop-owner memorizes the location of each tool, almost by feel, so that he can quickly access them for the job at hand.

Each tool has its own unique purpose and is shaped and patterned for that purpose!

Every blacksmith takes great pride in his work, knowing that it is distinctly unique from the next smith's work. The blacksmith signs his work in the form of a touchmark, which can be his initials or his shop name abbreviation. My stamp is a triple "F" for the "Fiery Furnace Forge" blacksmith company. In tools, it is often wise to stamp the type of steel that the tool is made from. (This is for future reference if the tool needs to be repaired or replaced.)

Here are some tools of mine, one marked "FFF S" for my shop name and then "Spring" meaning that the tool was made from spring steel, and the other marked "FFF H13" since it is made from a special hard metal known as H-13.

Other important tools include the blacksmith's trusty vise:

A swage block for forming difficult shapes like this shovel head swage:

And the smith's ever-growing assortment of tongs for holding hot metal!

Now,

What is the blacksmith's historical signifigance?

The blacksmith is a craftsman nearly as old as the world itself.....and let me specify that I am not talking about billions, or millions, or even hundreds of thousands of years.

The earth is around six thousand years old, give or take a few years, based upon the foundation of Holy Scriptures!

After proceeding only four chapters into the first book of the entire bible, we find the first blacksmith of sorts. Chronological study places this writing about 3900 years BC.

Gen 4:22

"And Zillah, she also bare Tubalcain, an instructer of every artificer in brass and iron: and the sister of Tubalcain was Naamah."

(Authorized King James Version of 1611)

Mr. Tubalcain is the first blacksmith mentioned, and quite probably the first blacksmith period.

You see, at the time, agriculture was the main occupation. This required tools to work the ground. Apparently iron and its value were discovered rather quickly and the blacksmith was born.

Over history, every other craft and occupation began to require the blacksmith's work.

Carpenters needed hammers, plainers, draw knives, drills, and nails.

Woodsmen need axes, chain, and logging hooks.

Hunters needed swords, knives, and arrowheads.

The armies of the day needed swords, daggers, shields, lances, spears, pikes, armour, etc.

Anyone that had need of a horse, had need of a smith to make buckles, saddle hardware, and shoes.

Anyone with a carriage, wagon, or horse-drawn sled, required the blacksmith's work for parts.

Early cars and tractors could even be repaired by the blacksmith.

Now here we need to make a distinction. A blacksmith was not the craftsman that made weaponry, horseshoes, or wagon parts. The same heating and hammering techniqes were used in these branches of blacksmithing, but the men who made these weapons and parts were not necessarily blacksmiths.

Medieval weaponry was produced by the bladesmith.

Medieval armour was produced by the armourer.

Wagon and carriage parts were produced by the wheelright.

The horseshoes were supplied and applied by the farrier.

Each of these branches of iron work shared the methods of the blacksmith, but the work itself was described in more specific terms.

The blacksmith was in charge of the creation of general farm hardware: hinges, latches, locks, nails, hammers, general tools, handles, gates, etc. etc!

As more items made from steel became mass-produced, the blacksmith had to take on more catagories of work until he was functioning as a farrier, wheelright, armourer, and bladesmith as well. So now the question stands to be answered:

Is there a place for the blacksmith in modern society?

Well, if you are a blacksmith and you go to a social event after a day's worth of smithing, you'll smell like sweat and be covered in coal dust, so you will not have much of a place in modern society in that sense!

However, that is not what I am speaking of!

There is a place for the blacksmith in the modern world.

In doing the craft fairs, I have come across scores of people who say "oh look a blacksmith, there aren't many of them left!"

OK! NEWS FLASH! Blacksmiths are NOT extinct! I am on a blacksmith forum with over 17,000 members worldwide, and it has well over 200,000 posts.

Lost art?

Just a few left?

Keep the craft alive?

I've heard them all, but there are still many blacksmiths around. Just in our small town, I know of two full-time smiths, a learning smith, and a retired smith. In about a three hour radius of our place, I could name a dozen right off.

But a lingering question may remain.

The military hasn't used armour or swords in a while; blacksmiths don't make tanks!

There aren't enough wagons rolling around to keep 17,000 blackmiths in work.

There aren't too many carpenters that get their hammers and tools from the blacksmith anymore, and doorknobs and locks can be bought for a few dollars by the hundreds.

What does a blacksmith do?

The modern-day, professional blacksmith creates ornamental, functional, and architectual iron work.

OK! NEWS FLASH! Blacksmiths are NOT extinct! I am on a blacksmith forum with over 17,000 members worldwide, and it has well over 200,000 posts.

Lost art?

Just a few left?

Keep the craft alive?

I've heard them all, but there are still many blacksmiths around. Just in our small town, I know of two full-time smiths, a learning smith, and a retired smith. In about a three hour radius of our place, I could name a dozen right off.

But a lingering question may remain.

The military hasn't used armour or swords in a while; blacksmiths don't make tanks!

There aren't enough wagons rolling around to keep 17,000 blackmiths in work.

There aren't too many carpenters that get their hammers and tools from the blacksmith anymore, and doorknobs and locks can be bought for a few dollars by the hundreds.

What does a blacksmith do?

The modern-day, professional blacksmith creates ornamental, functional, and architectual iron work.

This work can range from a simple triangle dinner bell to large elaborately-designed gates and railings.

Anything is possible with hot iron! The idea is to create a quality piece that is distinctly unique from mass-produced items from China or elsewhere abroad! The blacksmith uses high quality solid steel in place of thin piping, solid forge welds and rivets instead of conventional welds, and elegant flowing scrolls instead of choppy and uneven curves.

All in all, the blacksmith and his craft are alive and well. As long as steel and coal is to be had, and time is here, the blacksmith will continue to work his metal with the forge, anvil, and hammer!

"The smith with the tongs both worketh in the coals, and fashioneth it with hammers, and worketh it with the strength of his arms:...."

Dave Custer

Blacksmith

Fiery Furnace Forge Blacksmith Company

http://www.custerfamilyfarm.com/