Dave's Discourse

Me blog about meself! Ramblings of blacksmithing, sailing, and my general work around my place!

BE SURE TO CHECK OUT MY BLOG PAGES IN THE WHITE LINKS ABOVE!!!

Wednesday, April 30, 2014

Being an assistant instructor

As many of my faithful readers know, much of my instruction and learning in the world of blacksmithing, has come through the John C. Campbell Folk School in Brasstown NC.

One of my main teachers there is Mr Clay Spencer, a well known, talented, and experienced smith. The new John C. Campbell blacksmith shop is actually named after Mr. Clay.

A few months ago, Mr Clay emailed me and asked me to be his assistant instructor for his advanced level, traditional joinery class, at the folk school.

I was able to accept and thus helped him teach the week-long class. We had a split class. I helped half of the students build a traditional joinery table, while Mr Clay helped the other half of the class make a traditional steel chest.

It was great fun, and a real honor, to be able to try to fill the position of assistant.

Here are a few quick pictures.

Traditional joinery class with Clay Spencer, 2014.

The table, my half of the class made.

The chest that Clay's half of the class made.

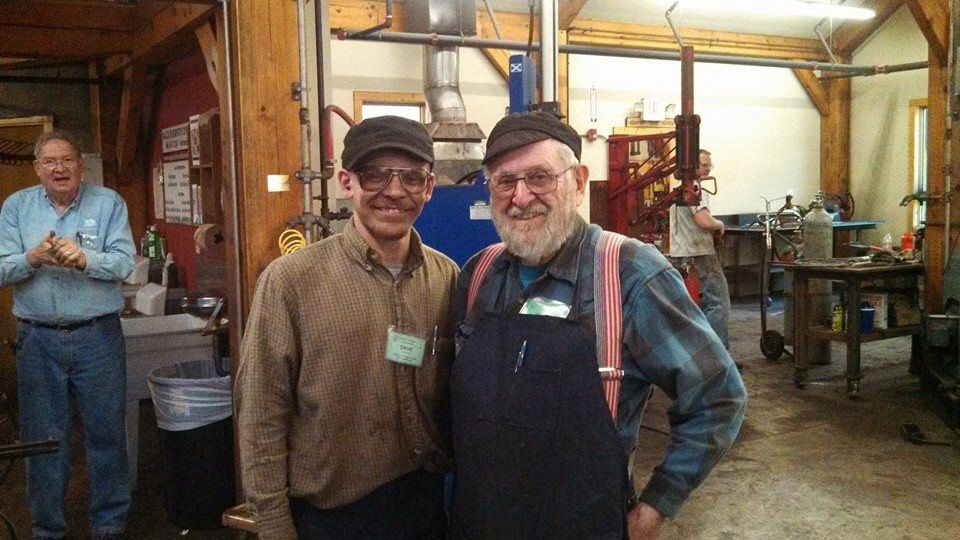

And here is a picture of me with the master himself, Mr Clay Spencer.

Monday, March 10, 2014

Some shop pictures and products

Shop work has been going by in a flurry. My goal is to have a minimum of $10,000 worth of iron-work to present to the public at the start of craft show season. This is a much higher volume of work than I have ever done at one time.

I am very busy producing my standard craft show items, but this year I am trying to get a few special pieces made to display and sell at shows as well.

First of all, here are some pictures of some standard products, laying around the shop, getting their final coats of finish before being put in inventory and packed away.

Also a couple weeks ago, my old touchmark broke. A touchmark is a blacksmith's way of signing his work. Just like an artist signs his paintings, the blacksmith likes to put his stamp on items he produces. My company name is Fiery Furnace Forge Blacksmith LLC, thus my touchmark has always been "FFF." Custom machined touchmarks are expensive, so I have always used a simple "F" stamp to stamp my three F's. A few years ago, I made my own touchmark. I have stamped literally, thousands of products with the stamp I made. It was a good touchmark, though it may have lacked the clean finished look of a custom mark. Well, like I said, my touchmark broke a few weeks ago. I have reverted back to the old "F" stamp as a "emergency" fill in, but I decided it was time to order a new custom touchmark. I did some research, located a company, and placed my order.

Here is my new mark. It is nice a clean and looks great!

In true blacksmith spirit, I had to make my own pair of touchmark holding tongs.

Another item I made recently, is a candle holder for pillar candles. This candle holder is free-standing. It is 40 inches tall, and 20 inches wide. It is designed to hold four pillar candles. Each holder is located 90-degrees to the previous one, and a little higher, creating a sort of upward spiral configuration. Also each holder bar is oriented to be 45 degrees to each leg, so that when viewed from above, you have eight equal divisions.

Here is an unfinished abstract piece forged from a large piece of left over hammer material.

Well this has been a long, picture saturated blog! Hope you've enjoyed it!

I am very busy producing my standard craft show items, but this year I am trying to get a few special pieces made to display and sell at shows as well.

First of all, here are some pictures of some standard products, laying around the shop, getting their final coats of finish before being put in inventory and packed away.

Leaves and crosses!

"Welcome" signs, made from horseshoes.

Here are some dinner bells, horseshoe napkin holders, horseshoe hearts, and horsehead bottle openers. Lots of all of them!

Here are a few hammers! I have gotten behind on hammers, because about two weeks ago, my belt grinder burned up. The belt grinder plays a critical role in hammer making, allowing me to quickly and properly grind the faces of the hammers I make. The grinder I built was underpowered and did not have the ideal type of motor on it, and after a year of grueling service, the motor gave out.

I immediately started a frantic search for a replacement motor. Replacement motors, especially the one I need for this application, are very costly. After some searching, a friend of mine, located a brand new, name brand motor, with all of the specs I needed, for about $100 less than what I would otherwise have paid. Now I just need to get the grinder frame built for the new motor, and I'll have the back up and running.

In the mean time, I have forged a few hammers, so I'll have some ready as soon as the grinder is back online.

Also a couple weeks ago, my old touchmark broke. A touchmark is a blacksmith's way of signing his work. Just like an artist signs his paintings, the blacksmith likes to put his stamp on items he produces. My company name is Fiery Furnace Forge Blacksmith LLC, thus my touchmark has always been "FFF." Custom machined touchmarks are expensive, so I have always used a simple "F" stamp to stamp my three F's. A few years ago, I made my own touchmark. I have stamped literally, thousands of products with the stamp I made. It was a good touchmark, though it may have lacked the clean finished look of a custom mark. Well, like I said, my touchmark broke a few weeks ago. I have reverted back to the old "F" stamp as a "emergency" fill in, but I decided it was time to order a new custom touchmark. I did some research, located a company, and placed my order.

Here is my new mark. It is nice a clean and looks great!

In true blacksmith spirit, I had to make my own pair of touchmark holding tongs.

Back to products:

For several years now, I have had a 6-inch diameter piece of steel pipe laying around the shop. It was some left over piece of something for some job past and gone.

I have long desired to make a bell from the piece of pipe, but it has been stubbornly decorating my shop floor day by day, week by week, month by month, and year by year.

Finally, I have taken the time to make the bell. It was a successful project and it rings well, like a bell.

Here is a bracket I made to hang the bell from.

Another item I made recently, is a candle holder for pillar candles. This candle holder is free-standing. It is 40 inches tall, and 20 inches wide. It is designed to hold four pillar candles. Each holder is located 90-degrees to the previous one, and a little higher, creating a sort of upward spiral configuration. Also each holder bar is oriented to be 45 degrees to each leg, so that when viewed from above, you have eight equal divisions.

Here is an unfinished abstract piece forged from a large piece of left over hammer material.

Well this has been a long, picture saturated blog! Hope you've enjoyed it!

Monday, February 17, 2014

new camera, more hammers, and general updates

Hi folks!

Here recently I purchased a nice new camera for photographing my blacksmith work. Many of the shows that I do are "juried" shows. This means that a jury panel reviews my work, via pictures, to determine if they want to allow me in the show.

Basically I get about 30 seconds of photo slides to impress the jurors enough so that they know they want me in their show.

You can probably guess that photo quality is pretty important, for my shows.

So, I sought the counsel of a number of photographers, hobbyist photographers, and blacksmiths who photograph their work, and settled on a Cannon Rebel T3i. I purchased a few additional gadgets that were recommended as well.

So now I at least have the potential to take some really nice photos. I just need to practice up.....oh yeah, and finish reading the 319 page owners manual.

Anyway, here are some miscellaneous photos from my new camera.

Here is ME!

Here is my next younger brother!

Here recently I purchased a nice new camera for photographing my blacksmith work. Many of the shows that I do are "juried" shows. This means that a jury panel reviews my work, via pictures, to determine if they want to allow me in the show.

Basically I get about 30 seconds of photo slides to impress the jurors enough so that they know they want me in their show.

You can probably guess that photo quality is pretty important, for my shows.

So, I sought the counsel of a number of photographers, hobbyist photographers, and blacksmiths who photograph their work, and settled on a Cannon Rebel T3i. I purchased a few additional gadgets that were recommended as well.

So now I at least have the potential to take some really nice photos. I just need to practice up.....oh yeah, and finish reading the 319 page owners manual.

Anyway, here are some miscellaneous photos from my new camera.

Here is ME!

And ME again!

Here is my next younger brother!

My youngest brother!

Banjo time!

My mandolin!

I play an Eastman!

My dog Cookie! She ain't nothin but a hound dog!

I have a long commute....it's like 300 feet! That's the shop, as seen from the front porch of the house!

Muddy boots! Just a fact of life back in the country.

Detail photo of a fireplace set I made.

A 4-pound hammer, cooling off after forging.

I have a warm heart.

A 2-pound hammer.

When I do shows and people find out that I am a full-time, self-employed blacksmith, at 21 years of age, one of the most common questions I get is, how did you get into blacksmithing.

My response is, I saw a blacksmith demonstrate at a Civil War reenactment. While this is what directed me to the vocation I now hold, the answer runs much more deeply than that.

It runs back to when my parents decided to homeschool their kids, instead of sending them to public school. It runs back to my parents making that decision based on biblically-based Christian values. It runs back to them teaching me to work hard, be responsible, do good work, be teachable, etc.

Everything they've taught me, and thus the way my character and personality have been shaped, revolve directly around a home of bible-based Christianity.

While many of my readers may think it strange or even foolish, my life has been built and it now stands firmly grounded on a book: The Authorized King James Bible of 1611.

Proverbs 15:3 The eyes of the LORD are in every place, beholding the evil and the good.

Proverbs 16:3 Commit thy works unto the LORD, and thy thoughts shall be established.

Monday, December 2, 2013

Yes I'm still alive!

So it has been quite some time since my last blog. August 26 was my last post. WOW!

OK so what in the world have I been doing all of this time????

Mostly work has kept me busy. Shortly after my last post, I had quite a bit of work getting ready and keep stocked up for fall art shows. Business was great at the shows, and has been ever since.

I have made so much stuff over the past few months that it would be impossible to show pictures of everything, but I'll share a few little things that I tinkered with.

Her are some horseshoe items I did for a lady.

This next piece is something I made for myself just for the fun of it. It is a little short-sword made from spring steel. I can bend over 45 degrees without staying bent, or breaking.

I have been manufacturing and selling more and more tools lately. Here are some blacksmith tools in the works, piled under the forge, waiting the next process.

Here is a "hold fast" that I made for a wood worker. I actually made several for him.

Back in September, I got together with my striker, Chase Saxton, and we made a run of hammers and went to the Quadstate SOFA blacksmith's conference in Troy Ohio. We had a great time up there selling tools, watching demos, buying stuff, and making new friends. Quadstate conference is one of the largest blacksmithing conferences in the country, and features the largest tool sales section of any conference. One of the highlights of the conference was the blacksmithing competition. There were a total of 32 people in the competition, and they were divided up into teams of two. Chase and I signed on as a team. The competition was to make as many nails as you could in 15 minutes. The nails had to be a minimum of 2-inches long, and were judged on quality and consistency. After the 15 minutes was up, each team got to pick their best five nails to submit. We made a total of 9 or 10 nails.

We were up against several really talented smiths, including my teacher, a guy that specializes in colonial work, and some others.

We came in first place and won the competition, which we were of course, thrilled about. My teacher came in second place, and the guy that does the colonial work came in third. It was a really fun time.

After the conference, my Chase and I parted ways. We've been friends for several years now, and have been making hammers to sell for about a year. However, we have some different views on work and some other things, and ultimately I decided it was the best move for my business to start doing hammers without him.

My dad and I now make the hammers that I sell.

I have been invited to teach at a school in the north east called Peter's Valley school of craft. I will be teaching, Lord willing, a 5-day class there next August. That should be interesting.

In addition, I am in the process of planning a one-day workshop in Knoxville Tn. sometime in January or February. More updates on that as plans get more solid.

Over the Thanksgiving holiday I made my grandad a knife that he'd asked for some time back. It is made from 5160 spring steel. The guard is stainless steel, the rivets are copper, and the handle is red cow bone. My brother made the sheath.

I don't normally do "abstract" art, but the other day I was inspired by a blacksmith in France, to do this piece. He did a similar one and I thought it looked pretty neat, so I made my own version. I can see making time to do more of this sort of thing in the future.This piece was actually made from a car axle.

To cap off the night, I figured I'd share a picture of something I didn't make. I never want to pass up an opportunity to brag on my sister, so here goes. My sister made this apple pie for Thanksgiving. Not only was it the worlds MOST BEAUTIFUL apple pie, but I think it was the best tasting one as well.

'Till next time!

"For God and the soldier we adore,

In time of danger, not before,

The danger past and all things righted,

God is forgotten and the soldier slighted."

Rudyard Kipling

OK so what in the world have I been doing all of this time????

Mostly work has kept me busy. Shortly after my last post, I had quite a bit of work getting ready and keep stocked up for fall art shows. Business was great at the shows, and has been ever since.

I have made so much stuff over the past few months that it would be impossible to show pictures of everything, but I'll share a few little things that I tinkered with.

Her are some horseshoe items I did for a lady.

This next piece is something I made for myself just for the fun of it. It is a little short-sword made from spring steel. I can bend over 45 degrees without staying bent, or breaking.

I have been manufacturing and selling more and more tools lately. Here are some blacksmith tools in the works, piled under the forge, waiting the next process.

Here is a "hold fast" that I made for a wood worker. I actually made several for him.

Back in September, I got together with my striker, Chase Saxton, and we made a run of hammers and went to the Quadstate SOFA blacksmith's conference in Troy Ohio. We had a great time up there selling tools, watching demos, buying stuff, and making new friends. Quadstate conference is one of the largest blacksmithing conferences in the country, and features the largest tool sales section of any conference. One of the highlights of the conference was the blacksmithing competition. There were a total of 32 people in the competition, and they were divided up into teams of two. Chase and I signed on as a team. The competition was to make as many nails as you could in 15 minutes. The nails had to be a minimum of 2-inches long, and were judged on quality and consistency. After the 15 minutes was up, each team got to pick their best five nails to submit. We made a total of 9 or 10 nails.

We were up against several really talented smiths, including my teacher, a guy that specializes in colonial work, and some others.

We came in first place and won the competition, which we were of course, thrilled about. My teacher came in second place, and the guy that does the colonial work came in third. It was a really fun time.

After the conference, my Chase and I parted ways. We've been friends for several years now, and have been making hammers to sell for about a year. However, we have some different views on work and some other things, and ultimately I decided it was the best move for my business to start doing hammers without him.

My dad and I now make the hammers that I sell.

I have been invited to teach at a school in the north east called Peter's Valley school of craft. I will be teaching, Lord willing, a 5-day class there next August. That should be interesting.

In addition, I am in the process of planning a one-day workshop in Knoxville Tn. sometime in January or February. More updates on that as plans get more solid.

Over the Thanksgiving holiday I made my grandad a knife that he'd asked for some time back. It is made from 5160 spring steel. The guard is stainless steel, the rivets are copper, and the handle is red cow bone. My brother made the sheath.

I don't normally do "abstract" art, but the other day I was inspired by a blacksmith in France, to do this piece. He did a similar one and I thought it looked pretty neat, so I made my own version. I can see making time to do more of this sort of thing in the future.This piece was actually made from a car axle.

To cap off the night, I figured I'd share a picture of something I didn't make. I never want to pass up an opportunity to brag on my sister, so here goes. My sister made this apple pie for Thanksgiving. Not only was it the worlds MOST BEAUTIFUL apple pie, but I think it was the best tasting one as well.

'Till next time!

"For God and the soldier we adore,

In time of danger, not before,

The danger past and all things righted,

God is forgotten and the soldier slighted."

Rudyard Kipling

Subscribe to:

Posts (Atom)