Here I am forge welding the hinge pins together.

This is one of four hinge pins. The pins are 10 1/2-inches long and are made from 1-inch round bar. The "cap" on top is a separate piece attached by the traditional method of forge-welding. That technique is pictured above.

I am using standard square head bolts for mounting hardware on these hinges but the heads needed to be textured so as not to have a factory-produced appearance. I also made some square washers to give these bolts a more bulky appearance.

I am using standard square head lag screws for the hinge plate mounting hardware. The heads on the lag screws were also textured but they do not need a washer.

These are the original strap hinges before I straightened them.

Now unless you are a blacksmith reading this, this next part is going to sound a bit strange to you.

These are very old unique hinges, obviously hand forged incorporating traditional techniques like forge welding, hot cutting, and punching/drifting. As I laid the hinges across the fire and the color began to show throughout the metal and I brought the glowing red hinge and laid it across my anvil and started guiding the metal with my hammer, I thought to myself, "A blacksmith, who knows how long ago, was doing just what I'm doing. He was making these hinges, carefully forming the hinge barrels and testing how they rotated. He was punching the holes and testing them to the bolts he'd made for these hinges, and he was inspecting his forge welds to make sure they would stand the test of time." Like I said, you have to be a blacksmith to understand, but it was a priviledge to rework the work of a smith of days-gone-by.

Ok well ummm enough of that!

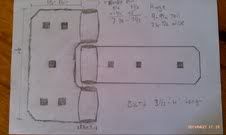

Here is the finished job: Hinge plates, hinge pins, straightened hinges, 20 lag screws, 12 bolts and nuts, and 24 washers.

(The large rusty bolt to the left in the picture below is one of the original bolts that was used to mount these hinges.)

That's all on the hinge job.

Here is a great song I came across the other day. It is the perfect picture of an honorable lady and gentleman (both seem to be in short supply but that is another blog for another day,) who have proven faithful and honest to one another over the years.