I made this last night. Thought it was an interesting little piece!

Me blog about meself! Ramblings of blacksmithing, sailing, and my general work around my place!

BE SURE TO CHECK OUT MY BLOG PAGES IN THE WHITE LINKS ABOVE!!!

Wednesday, August 24, 2011

Monday, August 22, 2011

slitting chisels

I made three slitting chisels the other day. These are for slitting a certain length cut in the middle of a piece of steel. I made three sizes: 3/8-inch, 1/2-inch, and 5/8-inch. I am hoping to make three more in 3/4-inch, 7/8-inch, and 1-inch.

I only have two pictured as the other was still getting painted when I got the camera out.

I also made some scroll tongs out of spring steel.

I only have two pictured as the other was still getting painted when I got the camera out.

I also made some scroll tongs out of spring steel.

Saturday, August 13, 2011

"Coal Mining"

Well, I am (or rather was) out of coal. I have a private source for coal and arranged to make a coal haul. The coal is in a basement adjoining a boiler room. The boilers were used over 20 years ago to heat a rather large building. The boiler room has a single light but the coal room is completely black.

I took enough containers to pick up about 2000 pounds of coal. (roughly 490 gallons) It is a hot, dirty, unpleasant, tiring, and dark job.

Dad, Kayla (my sister,) and I, go to get coal. I scoop the coal from the pile in five gallon buckets and carry them to dad in the boiler room, dad carries them up the stairs, and Kayla dumps them into the larger containers.

When said "private source" I did not mean I was stealing it.....this is really just to keep the dust out!

I took enough containers to pick up about 2000 pounds of coal. (roughly 490 gallons) It is a hot, dirty, unpleasant, tiring, and dark job.

Dad, Kayla (my sister,) and I, go to get coal. I scoop the coal from the pile in five gallon buckets and carry them to dad in the boiler room, dad carries them up the stairs, and Kayla dumps them into the larger containers.

When said "private source" I did not mean I was stealing it.....this is really just to keep the dust out!

Kayla at her station.........

Come on down into the basement!

Welcome to the boiler room....looks a bit like the Titantic. This is dad's station.

This is the coal room.......my station. With the flash it looks pretty light, but if you go in there you can't see your hand in front of your face. A flashlight only lights up what it is directly pointed at.

FINALLY done!

Voluteers for the next run?

Dave Custer

Fiery Furnace Forge Blacksmith LLC

Forge pipe fixed and new "toys"

As mentiond in a previous blog, the flue pipe which draughts the smoke off of my forge fire, has deteriorated and is no longer any good. I took this pipe down and this is what it looks like.

The metal inside the pipes is just pealing off in flakes. This is the inside of the forge hood that the pipe sits on top of. The pipe was litteraly collapsing from the inside out.

My plan of attack to fix this was to fabricate my own, heay duty, flue pipe. I puchased a 4x10 piece of sheet metal, made a jig, and started bending the metal into a pipe.

While the time spent on the sheet metal attempt was a complete loss, the money spent on it is not. I'm a blacksmith, and I can utilize just about any piece of metal. I have two, 2x8 metal tables that need a lower shelf. When I built the tables I made the frame for a lower shelf under the table top, however, I did not have the metal to finish the lower shelf. The metal initially intended for the pipe will now be used to finish these tables giving me some much need storage room.

Last week I did a bit of "splurging." I bought three pair of tongs! YAY! I have only ever bought one new pair of tongs before. I'm pretty much a tight wad and try to make my own tongs when I need them. However, there are several manufacturers that make very high quality tongs that are made to fit certain size pieces of metal perfectly. The right tool for the job is a LIFE saver. So I puchased three pair of tongs for some standard size material that I use frequently.

The metal inside the pipes is just pealing off in flakes. This is the inside of the forge hood that the pipe sits on top of. The pipe was litteraly collapsing from the inside out.

My plan of attack to fix this was to fabricate my own, heay duty, flue pipe. I puchased a 4x10 piece of sheet metal, made a jig, and started bending the metal into a pipe.

The sheet metal.

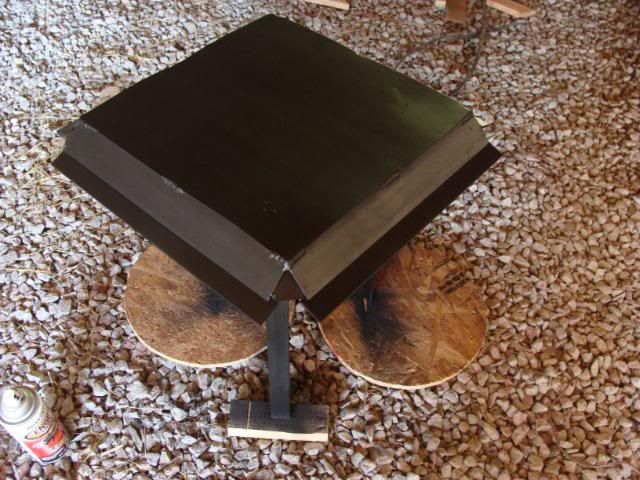

The 12" wooden disks for the jig.

The assembled jig and sheet metal ready for bending.

There is an extreme ammount of tension in benind something like this. I used three heavy-duty ratchet straps and started working.

It was very difficult to get to, and to get passed the stage shewn in the last photo. However, I made it and got the metal bent around and ready for welding. It took two days to get that far. I started welding but was unhappy with the shape of the pipe. Instead of a circle I had a trangle with bowed sides and an ocasionaly wrinkle. The seam along which I was welding was not flat, straight, or trim like I desired. In short, I'd spent 2 days making a pipe that looked like something that fell off a trailer on the interstate.

In short I abandoned this idea and broke down and bought some pipe. Actually I bought culvert drain pipe.

This required some modifications to the hood and rain cap, which I did and then repainted them.

And so the pipe was replaced.

While the time spent on the sheet metal attempt was a complete loss, the money spent on it is not. I'm a blacksmith, and I can utilize just about any piece of metal. I have two, 2x8 metal tables that need a lower shelf. When I built the tables I made the frame for a lower shelf under the table top, however, I did not have the metal to finish the lower shelf. The metal initially intended for the pipe will now be used to finish these tables giving me some much need storage room.

Last week I did a bit of "splurging." I bought three pair of tongs! YAY! I have only ever bought one new pair of tongs before. I'm pretty much a tight wad and try to make my own tongs when I need them. However, there are several manufacturers that make very high quality tongs that are made to fit certain size pieces of metal perfectly. The right tool for the job is a LIFE saver. So I puchased three pair of tongs for some standard size material that I use frequently.

I bought these from a place in North Carolina called Blacksmith's Depot. The comany that makes these tongs is Off Center Products. They are great, high quality American made tongs.

That's all for now!

Dave Custer

Fiery Furnace Forge Blacksmith LLC

Monday, August 8, 2011

a frog

I was in my shop today working on the new flue pipe for my shop, when I saw this frog. So I snapped some pictures for y'all. He'd make a good jig saw puzzle don't you think?

We had some storms come through the other night and had to clean this tree out the next morning. It was completely blocking the driveway but we got it cleared in a couple of hours.

Tuesday, August 2, 2011

Reminiscing

Having just experienced my one and only 19th birthday, I have decided to reminisce on the last year.

First of all let's cover my actual 19th birthday. My birthday is on the 31st of July and as already mentioned, it was my 19th. As an odd-ball little "woopsydaisy" I am legally one year older. According to my birth certificate I am 20 years of age. Now this might have been an understandable mistake if I had been born in January, but I was born seven months after the first of the year, and the lady still filled it out wrong. "Sumthin" to ponder on!

This year, my family was in Colorado visiting my Grandparents during the date of my birth. As such, my Grandparents kindly allowed me to choose a restaurant of my liking. I chose Italian! They chose a place, and it proved to be wonderful.

Now this is a reminiscing blog so I better get reminiscing.

Usually, when another year has passed in age, at least for me looking back, it seems that it has only been but a few weeks of time. This year has certainly been an exception! Really it has been the last year and a half or so, that have seemed to pass more slowly than before.

What has occurred in this past time?

Since turning 18 last year, I have been quite busy. Just after turning 18 I started attending intensive courses in blacksmithing at the John C. Campbell folk school. These courses have greatly increased my ability as a smith, being the first formal teaching in smithing that I have ever had.

Through God's grace I was able to gain the attention and approval of my first teachers and they used their influence to gain for me a position in some of the more advanced level classes that have driven me to work harder and learn more.

I did a few craft shows last year, demonstrating and selling my work, along with taking custom work.

Last October I did a craft show with the intention of visiting with someone I regarded as a friend during the craft show. When I returned home, I no longer could claim this person as a friend, the circumstances dictating that according to honor, I sever my ties with this so called friend. This person had proved dishonest and dishonorable in their actions toward me.

This event really got me down, but the Lord provided a good and true friend who helped me in time of need and strengthened me with straightforward advice. Looking with hindsight now, I see that these circumstances, however difficult at the time, were for the best and relieved me of a good deal of stress.

"All things work together for good to them that love God" Romans 8:28 in The Athorized King James Bible

Right around this time (October, 2010,) I had an offer of apprenticeship from a Master Blacksmith in Pennsylvania. This blacksmith is an incredible craftsmen with several helpers, and he specializes in extremely high-end artist metal work. I try to do good work but I have no idea why this guy picked me. I was very excited about this offer and we were tyring to plan a time when it would be possible for me to go. However, unforeseen circumstances prevented the realization of this wonderful opportunity. Regardless of this not panning out, it was a great honor to have been requested by someone with the skill this man possesses.

Also around this same time, I finally got a shop put in. We had been working on the shop project for quite some time, but in mid-late October, we finally got it dried-in, and my forge was installed. This was the first time my blacksmith shop was under a roof, and it felt wonderful....still does! I built a large shop forge, set up my large 280-pound shop anvil, put my treadle hammer inside, built tool racks and tables, and started organizing. All of this represents months of work and a substantial financial investment on my part. I do not spend much money on hobbies. Blacksmithing is my hobby as well as my business, so it is not an exaggeration to say that I put every spare dime into my business.

The last class I took at the John C. Campbell folk school in 2010 was Mr. Clay Spencer's advanced traditional joinery class. It was a hard class, and Mr. Clay taught us a lot. He is a great and knowledgeable smith and works hard to see that his knowledge is passed on.

I spent a good bit more time smithing this past winter than I did during the previous one. It is too cold in Kentucky most of the time to blacksmith in the open weather. However, with a shelter, I spent much more time at the anvil. I also spent a good bit of time building new tools, and improving my shop.

In February of 2011, I located a power hammer that was for sale in Fort Wayne, Indiana. A power hammer is an ESSENTIAL tool for a blacksmith who is making a living at the forge. You simply cannot compete without one. The power hammer I located, needed an industrial-sized air compressor to operate it, and I was able to locate one and arrange to pick up both pieces of equipment, on the same trip. My dad, my sister, and myself went to pick up these two pieces of equipment. The weather was fine when we left our house, but after we had purchased and loaded the compressor, the weather turned bad and cold. The result was a rather dramatic car crash after we hit a patch of ice on the interstate. In short we were driving in the slow lane heading North at about 40 MPH pulling a 20-foot flat bed trailer with the compressor on it. We hit ice and slid into the left lane, through the median, and into the oncoming traffic with the truck facing southward. We slammed into the guard-rail on the southbound side of the interstate, the trailer jack-knifed to the left side of the truck, and a Camaro smashed into the rear right side of our truck. My compressor was slung from the trailer about 50 feet, but by God's grace, sustained only about $40 worth of damage. The driver of the Camaro was dazed, but not injured and we were all OK. The truck was banged up a good bit but was drivable, enabling us to complete the trip, pick up the hammer, and make it back home.

It took a couple of weeks to get the hammer cleaned and painted, and the compressor repaired and installed. We had to run air lines throughout the shop and after about two months I had the hammer installed and in good working order.

We once again planned several craft shows for the spring, and I decided that I needed a more professional orderly, display along with something to carry that display in. I built a new forge and anvil stand for my demos, and purchased a large 12-foot enclosed trailer to haul my products in along with my display stuff.

Throughout the spring months I completed several custom jobs obtained through the craft shows I attend. On April 28th of 2011 I had the Fiery Furnace Forge Blacksmith Company made into the Fiery Furnace Forge Blacksmith LLC, a business entity legally recognized by the state of Kentucky.

Also during the spring I was offered another blacksmithing position by a Master Blacksmith on Manhattan Island, who needed help on some architectural work he is doing over the summer. Once again, circumstances did not allow me to take advantage of the offer, but it was an honor to be noticed for my work.

More recently I have attended a few more classes at the John C. Campbell folk school, along with my friend Chase Saxton.

Through all of this, dad and I have continued construction, when possible, on the shop. There is still much work to be done, but we are making marked progress.

Through all of this, the Lord has provided the means and strength for me to accomplish these tasks, difficulties, and projects set before me.

As you can see I have stayed quite busy between the ages of 18 and 19. Why has it seemed to pass so slowly then? That's a good question and one I am not prepared to answer. A lot has happened! Invaluable experienced has been gained and lessons learned, sometimes the easy way and sometimes the hard way. Mistakes were made, some costly! Good decisions were made, and the reward is seen.

A friend once asked me that if I could look into the future to see what decisions I would make and how my life would pan out, would I take that look?

My answer is no! That invaluable experience would then be lost, those lessons learned and mistakes made would have never happened, and as such I would not be the person I am now, and all hope of becoming the person I aspire to be would then be gone.

Now lies 'afore me, a new year!

First of all let's cover my actual 19th birthday. My birthday is on the 31st of July and as already mentioned, it was my 19th. As an odd-ball little "woopsydaisy" I am legally one year older. According to my birth certificate I am 20 years of age. Now this might have been an understandable mistake if I had been born in January, but I was born seven months after the first of the year, and the lady still filled it out wrong. "Sumthin" to ponder on!

This year, my family was in Colorado visiting my Grandparents during the date of my birth. As such, my Grandparents kindly allowed me to choose a restaurant of my liking. I chose Italian! They chose a place, and it proved to be wonderful.

Now this is a reminiscing blog so I better get reminiscing.

Usually, when another year has passed in age, at least for me looking back, it seems that it has only been but a few weeks of time. This year has certainly been an exception! Really it has been the last year and a half or so, that have seemed to pass more slowly than before.

What has occurred in this past time?

Since turning 18 last year, I have been quite busy. Just after turning 18 I started attending intensive courses in blacksmithing at the John C. Campbell folk school. These courses have greatly increased my ability as a smith, being the first formal teaching in smithing that I have ever had.

Through God's grace I was able to gain the attention and approval of my first teachers and they used their influence to gain for me a position in some of the more advanced level classes that have driven me to work harder and learn more.

I did a few craft shows last year, demonstrating and selling my work, along with taking custom work.

Last October I did a craft show with the intention of visiting with someone I regarded as a friend during the craft show. When I returned home, I no longer could claim this person as a friend, the circumstances dictating that according to honor, I sever my ties with this so called friend. This person had proved dishonest and dishonorable in their actions toward me.

This event really got me down, but the Lord provided a good and true friend who helped me in time of need and strengthened me with straightforward advice. Looking with hindsight now, I see that these circumstances, however difficult at the time, were for the best and relieved me of a good deal of stress.

"All things work together for good to them that love God" Romans 8:28 in The Athorized King James Bible

Right around this time (October, 2010,) I had an offer of apprenticeship from a Master Blacksmith in Pennsylvania. This blacksmith is an incredible craftsmen with several helpers, and he specializes in extremely high-end artist metal work. I try to do good work but I have no idea why this guy picked me. I was very excited about this offer and we were tyring to plan a time when it would be possible for me to go. However, unforeseen circumstances prevented the realization of this wonderful opportunity. Regardless of this not panning out, it was a great honor to have been requested by someone with the skill this man possesses.

Also around this same time, I finally got a shop put in. We had been working on the shop project for quite some time, but in mid-late October, we finally got it dried-in, and my forge was installed. This was the first time my blacksmith shop was under a roof, and it felt wonderful....still does! I built a large shop forge, set up my large 280-pound shop anvil, put my treadle hammer inside, built tool racks and tables, and started organizing. All of this represents months of work and a substantial financial investment on my part. I do not spend much money on hobbies. Blacksmithing is my hobby as well as my business, so it is not an exaggeration to say that I put every spare dime into my business.

The last class I took at the John C. Campbell folk school in 2010 was Mr. Clay Spencer's advanced traditional joinery class. It was a hard class, and Mr. Clay taught us a lot. He is a great and knowledgeable smith and works hard to see that his knowledge is passed on.

I spent a good bit more time smithing this past winter than I did during the previous one. It is too cold in Kentucky most of the time to blacksmith in the open weather. However, with a shelter, I spent much more time at the anvil. I also spent a good bit of time building new tools, and improving my shop.

In February of 2011, I located a power hammer that was for sale in Fort Wayne, Indiana. A power hammer is an ESSENTIAL tool for a blacksmith who is making a living at the forge. You simply cannot compete without one. The power hammer I located, needed an industrial-sized air compressor to operate it, and I was able to locate one and arrange to pick up both pieces of equipment, on the same trip. My dad, my sister, and myself went to pick up these two pieces of equipment. The weather was fine when we left our house, but after we had purchased and loaded the compressor, the weather turned bad and cold. The result was a rather dramatic car crash after we hit a patch of ice on the interstate. In short we were driving in the slow lane heading North at about 40 MPH pulling a 20-foot flat bed trailer with the compressor on it. We hit ice and slid into the left lane, through the median, and into the oncoming traffic with the truck facing southward. We slammed into the guard-rail on the southbound side of the interstate, the trailer jack-knifed to the left side of the truck, and a Camaro smashed into the rear right side of our truck. My compressor was slung from the trailer about 50 feet, but by God's grace, sustained only about $40 worth of damage. The driver of the Camaro was dazed, but not injured and we were all OK. The truck was banged up a good bit but was drivable, enabling us to complete the trip, pick up the hammer, and make it back home.

It took a couple of weeks to get the hammer cleaned and painted, and the compressor repaired and installed. We had to run air lines throughout the shop and after about two months I had the hammer installed and in good working order.

We once again planned several craft shows for the spring, and I decided that I needed a more professional orderly, display along with something to carry that display in. I built a new forge and anvil stand for my demos, and purchased a large 12-foot enclosed trailer to haul my products in along with my display stuff.

Throughout the spring months I completed several custom jobs obtained through the craft shows I attend. On April 28th of 2011 I had the Fiery Furnace Forge Blacksmith Company made into the Fiery Furnace Forge Blacksmith LLC, a business entity legally recognized by the state of Kentucky.

Also during the spring I was offered another blacksmithing position by a Master Blacksmith on Manhattan Island, who needed help on some architectural work he is doing over the summer. Once again, circumstances did not allow me to take advantage of the offer, but it was an honor to be noticed for my work.

More recently I have attended a few more classes at the John C. Campbell folk school, along with my friend Chase Saxton.

Through all of this, dad and I have continued construction, when possible, on the shop. There is still much work to be done, but we are making marked progress.

Through all of this, the Lord has provided the means and strength for me to accomplish these tasks, difficulties, and projects set before me.

As you can see I have stayed quite busy between the ages of 18 and 19. Why has it seemed to pass so slowly then? That's a good question and one I am not prepared to answer. A lot has happened! Invaluable experienced has been gained and lessons learned, sometimes the easy way and sometimes the hard way. Mistakes were made, some costly! Good decisions were made, and the reward is seen.

A friend once asked me that if I could look into the future to see what decisions I would make and how my life would pan out, would I take that look?

My answer is no! That invaluable experience would then be lost, those lessons learned and mistakes made would have never happened, and as such I would not be the person I am now, and all hope of becoming the person I aspire to be would then be gone.

Now lies 'afore me, a new year!

Subscribe to:

Posts (Atom)