Upon the conclusion of the class in Billings Montana, we started the long trip down the foothills of the Rocky Mountains on I-25, toward Texas. We stopped in Denver where my Grandparents picked me up and took me to eat. It was fun visiting with them.

From there we continued South, traveling through the North East corner of New Mexico before crossing into the Lone Star State. Almost there right????? HA! We still had a good day and a half or more of travel within Texas. We finally reached Houston area on a Tuesday afternoon. We unloaded the tools at the shop where we would be demoing on the upcoming Saturday, transfered our luggage to Daniel's Dad's car, and the four young smiths hit the road again for a 2-hour journey to Daniel's place. On the way, Daniel's Dad, Chris, treated us to a fine Texas steak-house meal (including dessert.)

We spent the next three days working (at a more relaxed pace,) in Daniel's shop, making a few odds-n-ends. We also made two gifts, one for our mentor Mr. Brian Brazeal, and one for his assistant and the only driver on the entire trip, Mr. Lyle Wynne.

Daniel and Alec employed themselves with the task of making a SUPER NICE Brian Brazeal-style hammer, for Brian, and Kainon and I made a bowl for Lyle.

The camera was packed up during the trip down the Rocky Mountain foothills, so I did not get any pictures of that, nor did I get any photos of us working in Daniel's shop. I do have a couple of good stories but I'll save those until after the pictures of our Saturday demo.

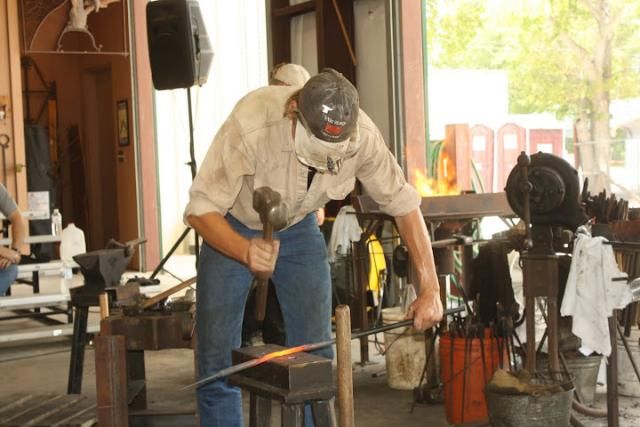

The demonstration that was schedualed was at the Lee Brother's Shop.....our kind hosts Jeff and Allan Lee. Their shop is a large, well-outfitted, full time blacksmithing opperation.

Enough talking! Here are some pictures!

The first half of our demo, we focused on tools. In the pictures above, Kainon and I made a hot-cut hardy and a slot punch while Daniel and Alec made a hammer. Then we all four came together and made a cupping tool. While Daniel and Alec finished up the cupping tool, I did a forge welding demonstration, making the cross shown in the last picture.

After our morning demonstration period, we at lunch and then had an auction. After the auction, we had an afternoon demonstration. In this demonstration, Kainon and I forged a bird (I directed, he struck,) and three sides of a rectangular frame. While we were so employed, Daniel and Alec made three cat-tail leaves, one cat-tail, then forge-welded them together, then forge welded them and the bird Kainon and I made to the fourth side of the frame. Once all of this was completed, All four of us came together to forge weld the bottom of the frame to the sides/top of the frame.

Here are some pictures of the process and the product!

This concluded the demonstrations and really concluded Young Smiths 2012. Shortly thereafter, Kainon departed, headed for his home in Austin, Texas. Before we left, however, we got to play with the "big-boy toys" of the shop. Namely, the 400 pound Nazel, self-contained air hammer. Drumroll please!

Alec, promptly heated up a piece of 1.5-inch solid round stock about 12 inches long. He took about a third of it, and forged it out under the hammer. This hammer delivers 400 pound hammer blows somewhere in the neighbourhood of 200 times a minute.

He forged it down a bit, but being unused to power hammers, did not have an overly large ammount of control.

Daniel was next up "to bat." He took the other end of the 1.5-inch solid round, again using about a third. No offence to Daniel, but he made a mess of it! (Sorry Daniel! :) ) To give him credit he did end up with a piece of "unintentional-art."

Being that there was a third young smith present, and there was a third of the original 1.5-inch solid bar left, I was "forced" into using the hammer. BIG MISTAKE! As I walked away to heat the metal up, Brian said, "Yeah, see how long you can draw that section out!" You see, I've used both air and mechanical hammers extensively, currently owning both types, and having used the various types of both hammers. The largest hammer I've ever used was a 135 pound air hammer, but the ones I use on a daily basis are a 60 and a 50 pounder. Roughly 1/8 the size of this hammer. However, the general method is the same, just upscaled a bit.

I was, at first, a little doubtful about the amount of control I would have over such a large hammer. To my pleasure, as soon as I touched the control pedal, I knew I could do it, and fell into the same rythm I use on my smaller hammers here in my shop.

In short, I made a perfectly straight, perfectly round bar about 15 inches long and something like 3/4-inch thick. As I used the hammer and moved more and more steel, sometimes running the hammer wide open at it's fastest and most powerful capacity. Quite frankly it was a blast!

There was a bit of cheering me on from the crowd once I got set into a steady pace. Once I had finished, one of the shop owners (Jeff Lee,) ran over and grabbed my arm, threw it in the air and shouted, while someone else yelled "And we have the WINNER," with Alec's voice in the background shouting, "That was incredible!"

Here is Alec inspecting my work!

Passing it to the next person waiting to see it!

It seems I was king of the moment, and I enjoyed every second of it! It was great fun running such a large and powerful hammer, with such pleasing results.

That pretty much concludes the pictoral tour of Young Smiths 2012. I did say though, that I had a couple of good stories to tell.

One took place while traveling over the Texas plains! I had, up until this time, never seen a real dust devil. Texas has some sure-nuff real dust devils. There were dust devils several hundred feet high and 50 feet around, swirling like mad, across the, more or less dessert lands. To make it more amazing, there were several of these within sight, quite often. Once, while we were driving down the road, one of these large dust devils collided with our truck. The impact was audible and shook the entire truck with amazing force. It was quite an interesting experience.

The second story took place in Daniel's shop. Kainon and I were working on the bowl we were making for Mr. Lyle. We forged the bowl from a piece of 2-inch solid round steel, 1/2-inch thick. It started out as a thick disk and we thinned it down to about 1/16-inch thick and 6-inches around. It was quite an difficult task. When the metal is that thin, it cools very quickly, only giving time for a couple of hammer blows, before it must be reheated. Once, while we were working, Daniel threw a huge chunk of ice into the bowl. The bowl (still around 800 degrees Fahrenheight,) began melting the ice rapidly with a loud crackling and sizzling sound. I looked at Daniel with irritation! Then I looked at the bowl, which was held with tongs. He seemed to read my mind. It was a perfect catipult for the remaining ice and boiling water. He took off, but not before I could hurl the mixture of EXTREMELY cold ice and EXTREMELY hot water in his directly. The ice missed him, but a large bit of water hit his shirt, encourging some outragous dancing performances!

As a part of the four Young Smiths group, I can tell you, we had quite a few clashes and arguments during the month-long experience. However, we were all good sports and got over it and moved on. We all parted as friends!

From the Texas demo, Daniel went home, while Alec and I traveled back to Mississippi with Brian, Brian's wife, Lyle and Lyle's wife. (Ohhhh yes, and Brian's, wife's, dog!)

However, Young Smiths 2012 ended in Bryan, Texas at the Lee Brother's shop, so that's where I'll conclude!

And what better way to end than with a picture of us packing up!

Pack 'em up boys, were going home!